.jpg?width=1200&height=812&name=Trykeri_1%20(1).jpg)

At Seritronic, we manufacture and develop control panels, membrane keyboards, acrylic fronts, plastic signs and mechatronic solutions for any industry. We produce customized control panel solutions and take pride in being flexible, as well as process secure, to ensure the agreed quality. Our production is continuously developed and optimized, which means that we have the latest high-tech production equipment.

What is silk screen printing?

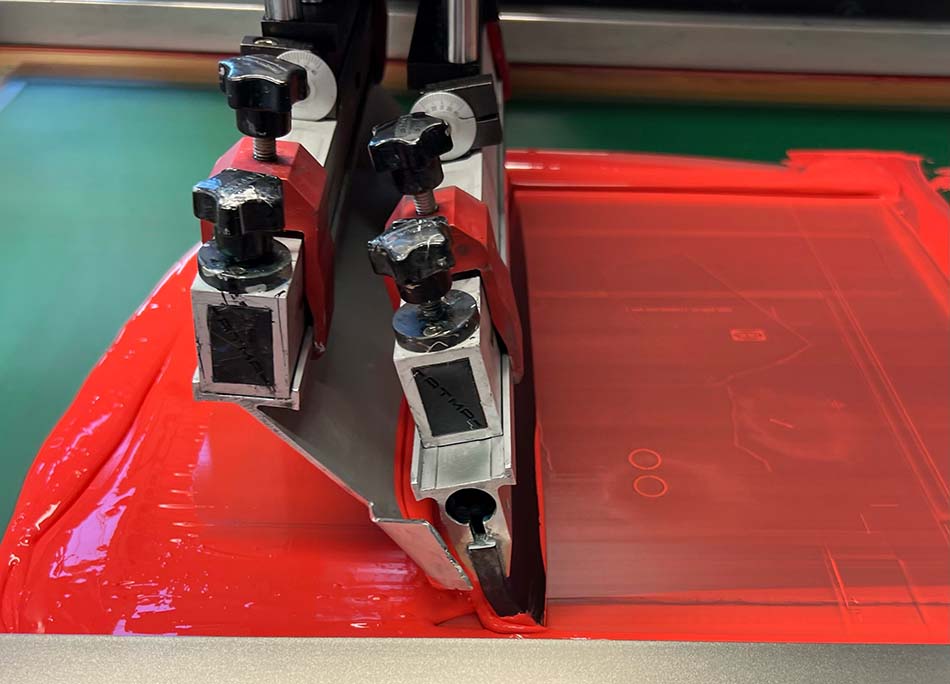

Silk screen printing is, an old, recognized printing method, and is also called serigraphy. The printing method was previously performed with silk cloth – which is why the production name was established. Today, the printing form is carried out with a metal frame on which is clamped with polyester cloth. In the polyester-consisting cloth, photo emulsion is added, in which the desired stencil occurs by exposing the areas to strong UV lighting.

Subsequently, the unscathed photo emulsion is washed away, and the stencil (image) appears. This is done in a fully automatic CtS (Computer to Screen) system with a resolution of 1270 dpi (dots per inch), which optimize and clarifies frame manufacturing. The printing method consists of printing selected colors on certain materials. This is done by pulling the color across the polyester cloth onto an underlying material.

Colors

In silk screen printing, every single color is a process. With each color, printed through one frame. The silk screen printing process is repeated for each color selected for the given product and repeated until the visual expression is achieved according to the design of the product. To secure the rightful color combinations, a spectral photometer is used. For example, if your membrane keyboard needs to match the colors of your enclosure, we can measure the enclosure and thereby customize the membrane keyboard colors to match your enclosure. The photometer also allows us to measure a given material and put it in as a filter, so we create the best conditions for being able to meet your color wishes. This applies to both Pantone, RAL and NCS colors.

The material on which the color is printed depends on the application environment of the finished control panel. It is of paramount importance with the right choice of material that considerations must be made for the foil's user environment. On materials used for front foils and membrane keyboards, the printing is made on the back of the selected material. This means that the color resistance and durability are endless and that it can be cleaned with most cleaning agents. Furthermore, in the silk screen printing process, the conductor paths included in a membrane keyboard are printed. These are printed with a conductive silver paste material.

Seritronics silk screen production

The silk screen printing production processes are all carried out by trained graphic technicians who have made the silk screen printing method their area of expertise. In our silk screen printing department, machine capacity ranges from manually operated pressure stations to fully automatic printing lines. We print products in varying sizes from 10mm up to the needs you have.

.svg)

.svg)

.svg)

.png?width=200&height=56&name=Mekoprint%20Seritronic%20Logo%20(1).png)

%20(1).jpg?width=1680&height=547&name=Trykeri_4%20(2)%20(1).jpg)